Tackle high-temperature exhaust emissions effortlessly! This highly sealed ventilation duct makes industrial operations more efficient.

Sep 27,2025

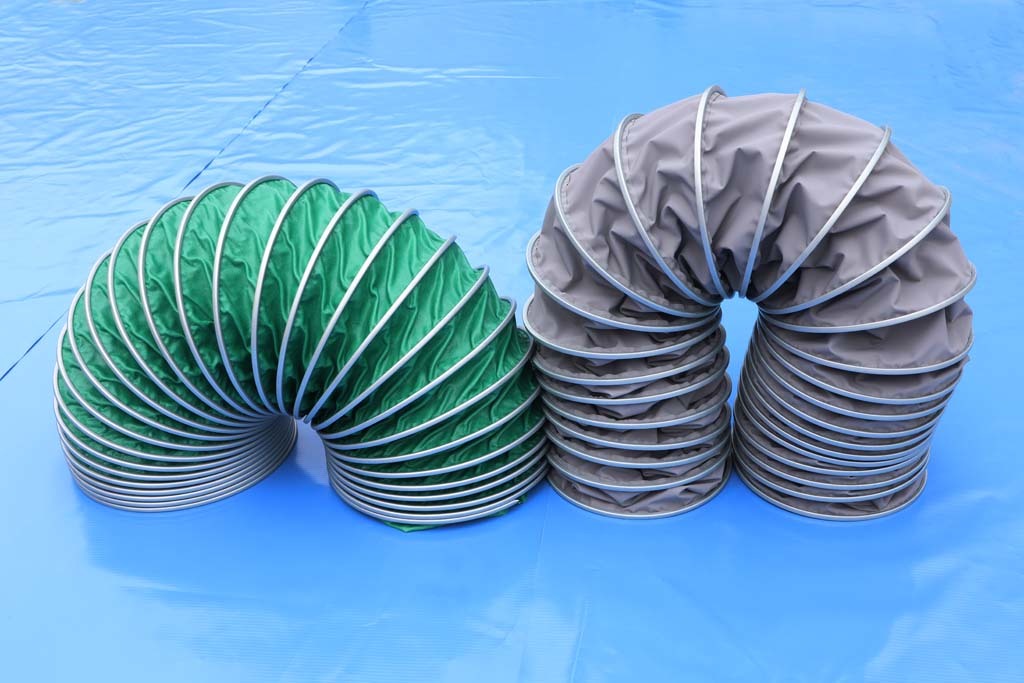

450°C Temperature-Resistant Expandable Duct

Utilizing high-quality, imported single-layer glass fiber-coated fabric paired with high-strength fiber threads as the core material, the product is precisely clamped at both ends with metal clips before being spirally formed and extended. This process results in exceptional sealing performance of the tube walls, completely eliminating any air leakage. The maximum pressure resistance can stably reach up to 5000 Pa, making it not only ultra-lightweight for easy installation and handling but also incredibly durable, boasting outstanding tensile and flexural strength. Its bending radius is approximately equal to its outer diameter, allowing it to seamlessly adapt to a variety of installation environments. Additionally, with a compression ratio of 1:10, the product achieves remarkable space efficiency during both retraction and extension.

Characteristics |

Three-Proof Fabric Telescopic Hose |

450°C Heat-Resistant Iron Clamp Tube |

Summary |

|

Temperature resistance range |

-30°C ~+210°C high-temperature resistance, but there’s still a noticeable difference compared to the 450°C iron clamp tube. |

- A super-wide temperature range from -70°C to +450°C, with a thermal shock resistance of up to 520°C, easily accommodating extreme conditions such as frigid cold or scorching heat—eliminating the need for frequent replacements while offering exceptional versatility. |

In terms of temperature resistance, the 450°C iron-clamp hose operates within a range of -70°C to +450°C, with a maximum temperature difference tolerance of 520°C. Compared to the three-proof fabric expansion hose (-30°C to +210°C), this model is better suited for a wider array of extreme environments—such as frigid cold or scorching heat—and thus offers greater versatility. |

|

Wear resistance |

Good It has good wear resistance, but is generally not as good as iron clip tubing. |

Excellent The coefficient of friction is extremely low, and the wear resistance is exceptionally excellent. |

In terms of wear resistance, the 450°C iron clamp tube boasts an extremely low coefficient of friction and outstanding durability, while the three-proof fabric retractable hose, though also offering good wear resistance, generally falls short compared to the iron clamp tube. Overall, the 450°C iron clamp tube demonstrates superior performance in both temperature resistance and wear resistance, making it more versatile and suitable for a wider range of applications. |

|

Mechanical Properties |

The ultra-thin 0.35mm tube wall design achieves lightweight benefits while maintaining structural strength. |

0.45mm enhanced thickness delivers exceptional strength and durability, making installation effortless. It not only reduces transportation and installation costs while minimizing space requirements but also boosts media transmission efficiency—perfect for specialized scenarios where weight and space are limited. |

From a mechanical performance perspective, the 0.35mm ultra-thin wall model prioritizes lightweight design while ensuring structural strength; the 0.45mm reinforced-thickness model emphasizes durability, ease of installation, cost reduction, space savings, and improved medium-transmission efficiency—making it ideal for specially constrained environments. |

|

Materials |

Three-proof fabric, stainless electroplated steel clip |

High-quality fiberglass fabric, gray high-temperature coating, and stainless electroplated steel clips |

In terms of materials, the former uses a three-proof fabric, while the latter employs high-quality fiberglass cloth with a gray high-temperature coating—giving the latter a distinct advantage in heat resistance and other performance attributes. Overall, each of the two options has its own unique features, allowing users to choose based on their specific needs for mechanical properties (such as lightweight design or suitability for specialized scenarios) or material characteristics (like standard durability versus high-temperature resistance).

|

Both provide Full-size aperture options ranging from 51mm to 1500mm , covering the entire spectrum of needs—from small-scale precision applications to large-scale industrial scenarios. Specifically, the small-caliber models precisely meet the meticulous, low-flow requirements of medium delivery in precision equipment, ensuring stable operation; meanwhile, the large-caliber models can handle high-flow demands in industries like manufacturing and municipal engineering, seamlessly integrating with various pipeline systems. Thanks to this comprehensive size coverage, both products eliminate the need for custom modifications, allowing them to flexibly adapt to diverse application scenarios while significantly reducing both selection costs and time-to-market expenses.

Suitable for ventilation and exhaust systems in various industrial machinery and equipment, it efficiently handles the emission and purification of automotive exhaust gases. It also delivers excellent collection and removal performance for fumes generated during high-temperature soldering operations. Additionally, this system can be applied to the circulation and transportation of scorching hot gases from high-temperature boilers, as well as in scenarios involving waste gas emissions, ensuring smooth gas flow across all stages while meeting environmental protection standards.

Rongxin Air Duct

Office Address: Room 401, Building 5, Lihe Kechuang Center, No. 101 Wanghu 1st Road, Shimeng Street, Baiyun District, Guangzhou City, Guangdong Province

Factory Address: No. 39 Chuangye Road, High-Tech Industrial Park, Jinshi City, Changde City, Hunan Province

Contact information: 13533685362 / 13825185211

Landline: 020-36010404

Website: www.gzrxfg.com www.rongx168.com

Emails: hjq@gzrxfg.com / hzw@gzrxfg.com / lxp@gzrxfg.com / wmin@gzrxfg.com

Related News